If you don’t know any better, that stuff looks identical to glass. It’s just not as heavy, so you probably want to know what material it is actually. Is acrylic plastic or something else entirely? Acrylic is indeed a type of clear plastic. It is one of the most common thermoplastic variants. The scientific name for acrylic is polymethyl methacrylate or PMMA for short. In layman’s terms, it’s a glass-like plastic that can do almost everything regular glass can. There are numerous plastic types, but what makes acrylic so versatile? It differs massively from prevalent plastic-like PVC, Polystyrene, or Polypropylene. I’m sure you also are curious about the relationship between acrylic and plexiglass. I’ll discuss everything you need to know about acrylic, starting with its manufacturing process- all the way to its pros and cons.

Difference Between Acrylic And Regular Plastic

The plastic material that an average person uses can be divided into two main archetypes. The first is thermoplastic- which has the defining characteristics of being recyclable. The other type is the thermosetting polymer that can not be recycled. Acrylic is a recyclable and clear plastic with a very high range of applications. Plastic is a term that encompasses a broad range of synthetic or semi-synthetic materials. Acrylic is merely one type of clear plastic that people have been using to substitute glass. The other Clear Plastics are Polycarbonate and polystyrene. Acrylic is stiff and has an extensive transparency level. But that’s about all it brings to the table. Polystyrene has excellent optical properties, but it lacks hardness and is quite brittle. That is why most of the faux glasses you see on the market do not come from polystyrene. The most common application of polystyrene is injection-molded packaging. Yes, it is the same stuff plastic bottles are made of, and it is quite a bit different from acrylic. Polycarbonate is more similar to acrylic in its hardness and clarity. But it is far more expensive than the latter. It massively outperforms acrylic in terms of hardness. Chances are you have heard of the high-end polycarbonate before. It is the same stuff they make bullet-proof glass out of.

How is Acrylic Plastic Made?

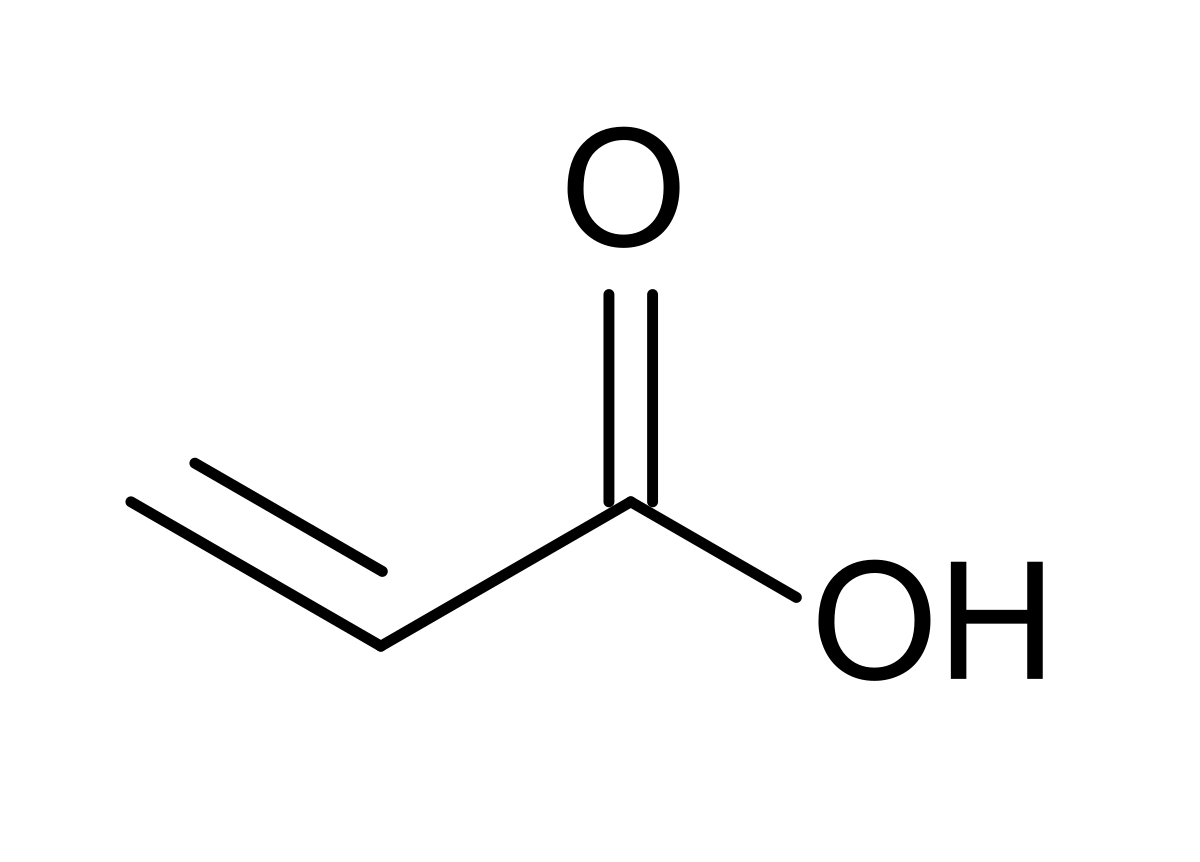

Plastic polymers are made by causing a reaction between a monomer and a catalyst- usually an organic peroxide. For acrylic, the monomer is usually methyl methacrylate.

There are three possible acrylic types one can get through this process. The flat sheet is the most common, followed by elongated tube or rod shapes. The last variant is the molding powder. Flat sheets are what most people call plexiglass. The elongated shapes are usually part of acrylic furniture. Most acrylic furniture is typically a combination of the first two types. The last one- molding powder is commonly seen in paint, lens, medical devices, and even fake nails. There are two ways to make traditional acrylic plastic, and I’ll give a brief overview of them both:

Hand-crafted

If anything has the word hand-crafted, it’s usually a sign of higher quality and price range. The hand-crafted acrylic is the most high-quality variant of this type of plastic. You can use it for making display cases or as a high-quality substitute for glass. The joints of hand-crafted acrylic are melted together with solvents. That gives it a much clearer finish than injection molding. The only downside of hand-crafted acrylic is that it is more expensive than regular acrylic. Also, the manufacturing process is more time-consuming, leading to a supply shortage.

Injection-molded

Injection molding is a manufacturing process where the primary material is injected into a mold. Manufacturers pour Poly (methyl methacrylate) in a suitable mold to make acrylic plastic. The injection-molded acrylic is far more functional compared to injection-molded Polystyrene. The finished product has a lot of imprints and opacity when one uses Polystyrene in the injection-molding process. The loss of transparency is the main reason why polystyrene is only used for cheap packaging. The acrylic created through this process does not have any opacity, so it still retains its defining quality. You would generally find injection-molded acrylic on sunglasses, bowls, display cases, or other high-end containers. Usually, there isn’t any hazing or coloration on the surface unless the manufacturer intends that. It is a relatively fast manufacturing process and has almost no labor cost.

Advantages of Acrylic Plastic

Acrylic is one of the oldest plastic materials we use to this day. But the consumption rate of this plastic continues to increase every year. Several positive aspects of acrylic plastic led to its widespread use. Some of them are:

High Transparency

Acrylic is one of the easiest to make see-through plastic. It has extremely high transparency and has a high grade of optical clarity. Moreover, it does not develop coloration or opacity; not even during the manufacturing process. That makes it easier to mass-produce. Acrylic may be clear, but the optical clarity is not too high after initial formation. It needs to go through multiple curing and vapor polishing to achieve the desired level of clarity.

Durable

Acrylic is the next best thing if you do not want to put bullet-proof glass. It is around ten times stronger than regular glass. It does not break into large chunks when hit. Instead, a sufficient amount of pressure would cause it to shatter. It is not shatter-proof- meaning it can still shatter. But it would take a lot of pressure to cause the shattering. The thickness of an acrylic sheet also has a positive influence on durability. Thicker acrylic sheets have a much higher impact resistance. The commercial acrylic sheets range from 0.06 inches to around 4 inches in thickness.

Easy To Reshape

Acrylic is much easier to handle compared to glass. You could cut it, reshape it, mold it, or even drill holes in it without much issue. But doing so requires experience and skills. Novices can easily break acrylic sheets while trying to mold them into shape.

Drilling acrylic plastic is relatively easier as long as you have proper tools. Experts tend to stick with ⅛ drill bits for the job. Slow drills are terrible at working with acrylic. You would need a fairly fast drill. Cutting acrylic plastic is easier. You can even do it with affordable tools like scoring knives. However, fine-tooth saw blades are better overall if you want a chip-free cut. The Dremel is a go-to tool if you want finer details on your acrylic. But you can make it fancier by taking it to a laser cutter.

Corrosion and Chemical Resistance

Acrylic plastic sees heavy usage in the medical and science field due to its resistance to a wide range of chemicals. This material is also resistant to corrosion and can withstand up to 160 degrees celsius, making it great for storage devices. The high resistance to temperature variation makes it ideal for medical microfluidics and manifolds. The temperature resistance is high enough for heat-treating too. People also make sample collectors and other analytical storage devices from acrylic. Related posts you must read Can Styrofoam Be Recycled Is Styrofoam Plastic Does Wood Float on Water Types of Humidity Does Cotton Grow on Trees Tsunami vs Typhoon Does Concrete Absorb Water Does Cork Absorb Water Does Aluminum Foil Burn Does Aluminum Conduct Electricity

Disadvantages of Acrylic Plastic

As with any synthetic material, there are several disadvantages of acrylic plastic.

Toxic Fumes

Acrylic plastic is very suitable for making containers and safety equipment, but the production process is filled with toxic hazards. The manufacturing process creates toxic substances and other fumes with highly toxic elements. Every worker needs expensive protective gear to work at acrylic plastic plants safely. That means the production cost is not as cheap as one would think. And the risks involved in this line of work are also substantial. It is not an easy task to dispose of all the waste material. There’s a chance that the polymerization process could lead to an explosion if you do not monitor it carefully. The production phase is not the only stage where it emits toxicity. The acrylic paint and powder can also contain toxic elements harmful to the human body. So, such things need a lot of caution while using.

Low Recyclability Rate

Did you know that most plastic products are not 100% recyclable? Even plastic with the three arrows recycle tag is not wholly recyclable. Acrylic is a group 7 plastic in the recycle chart. Group 7 is one of the lowest tiers for recycling. Manufacturers find it cheaper to make new acrylic plastic than to recycle existing ones in most countries. So it is very harmful to the environment. On top of that, It is a highly flammable material. It can handle high temperatures but not direct contact with flames.

Conclusion

Is acrylic plastic? I believe you have your answer. Yes, it is a type of plastic, and it is also a suitable substitute for glass. It is far more durable and lightweight compared to regular glass. However, its terrible synergy with the environment is a big downside. Happy learning!!